Introduction

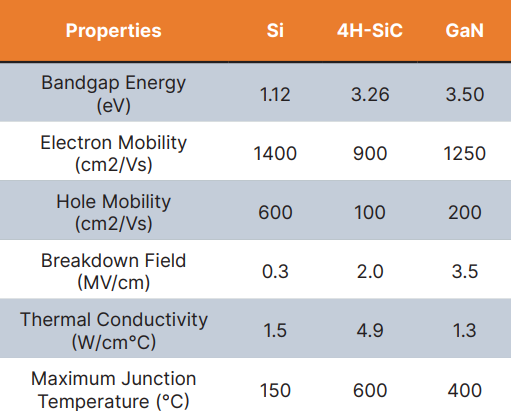

Power electronics rely heavily on semiconductors such as silicon (Si), silicon carbide (SiC), and GaN HEMTs. While Si has been the traditional choice, SiC devices are gaining popularity due to their superior performance and reliability. With its many technological advantages over Si (Figure 1), one can easily see why SiC has become the new go-to technology in many applications, such as electric vehicles (EVs), data centers and energy infrastructure such as DC fast charging, energy storage, and solar inverters.

What is SiC Cascode JFET Technology?

Many end-product manufacturers have adopted SiC over Si technology to develop their power supplies based on bipolar junction transistors (BJTs), junction gate field effect transistors (JFETs), metal oxide semiconductor field effect transistors (MOSFETs), and insulated gate bipolar transistors (IGBTs). They are used in different applications because they have different strengths and weaknesses.

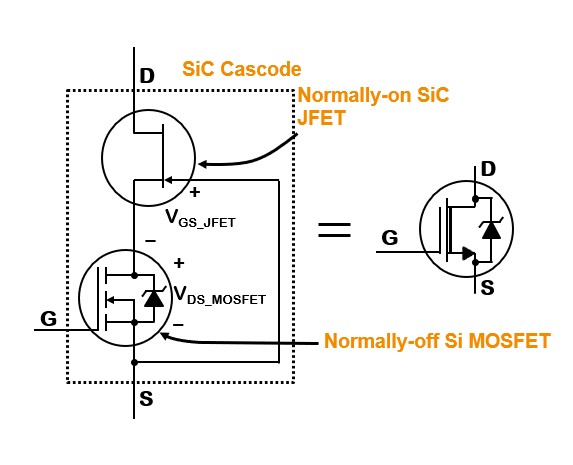

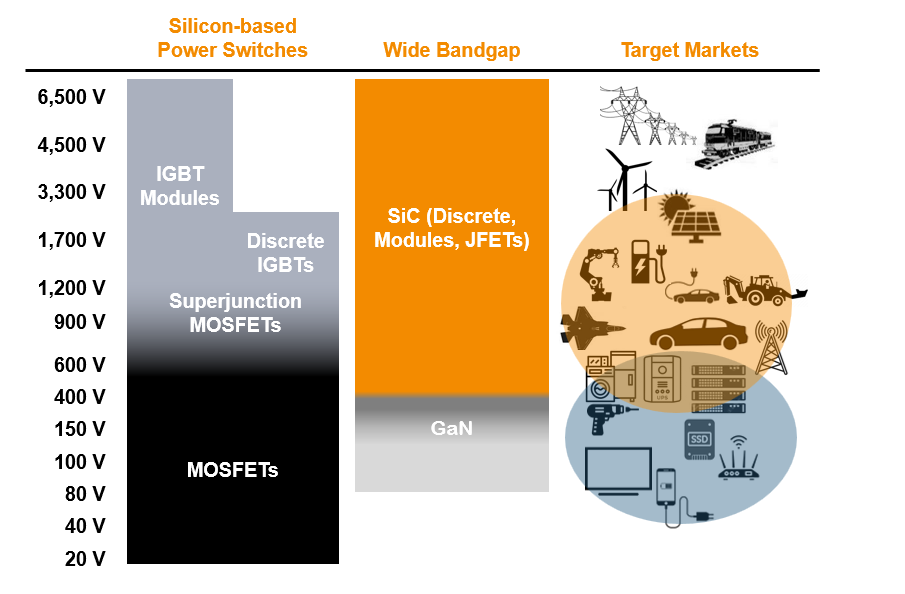

However, onsemi’s EliteSiC cascode JFET device (Figure 2) has taken the technology one step further. These devices are based on a unique ‘cascode’ circuit configuration, where a normally-on SiC JFET device is co-packaged with a Si MOSFET to produce an integrated normally-off SiC FET device. Our SiC cascode JFETs offer easy, flexible replacement of any device type such as IGBT, super-junction MOSFET, and SiC MOSFET. (Figure 3)

In this blog, we will explore the advantages of onsemi's EliteSiC cascode JFETs compared to their SiC MOSFET counterparts.

Advantages of Using SiC vs. Si

SiC cascode JFETs have several advantages over Si devices. SiC is a wide bandgap material which means it has higher breakdown voltage and a much thinner device can be used to support higher voltages. Other advantages of SiC over Si are:

- For a given voltage and resistance class, SiC enables higher operating frequencies and, hence, smaller size components, thus reducing the overall system size and cost.

- For the higher voltage classes (1200V or higher), SiC enables high-frequency switching with low power losses. Si devices in these voltage classes are essentially non-existent.

- In any given package, SiC enables lower on-resistance (RDS(ON)) and lower switching losses compared to Si.

- SiC delivers higher efficiency with better thermal performance and even higher system power ratings in the same design as Si

SiC Cascode JFETs: Simplifying Si to SiC Transition While Delivering Excellent Performance

These advantages also fold into the performance of the onsemi EliteSiC cascode JFETs, a newer but more powerful device optimized for several power applications.

Compatible with Si Gate Drivers: Enabling a Seamless Transition to SiC

First, the architecture of SiC cascode JFETs allows the use of standard Silicon (Si) gate drivers. This simplifies the transition from Si-based designs to SiC, offering greater design flexibility. They are compatible with a variety of gate driver types, including those designed for IGBTs, Si Superjunction MOSFETs, and SiC MOSFETs.

Additional Advantages

- Lowest industry drain-to-source on-resistance RDS(ON), for a given package which maximizes system efficiency

- Lower capacitance allows even faster switching, hence higher operating frequency; this further reduces the size of the bulky passive components like inductors and capacitors

- SiC cascode JFETs in higher voltage classes (1200V or higher) enable higher operating frequencies when compared to Si IGBTs, which traditionally service this market segment but are generally sluggish and used only at lower frequencies, resulting in higher switching losses

- The onsemi EliteSiC cascode JFET device enables smaller die size for a given RDS(ON), and mitigates the gate oxide reliability concerns typical in SiC MOSFETs

A Closer Look at SiC MOSFETs vs. onsemi SiC Cascode JFET

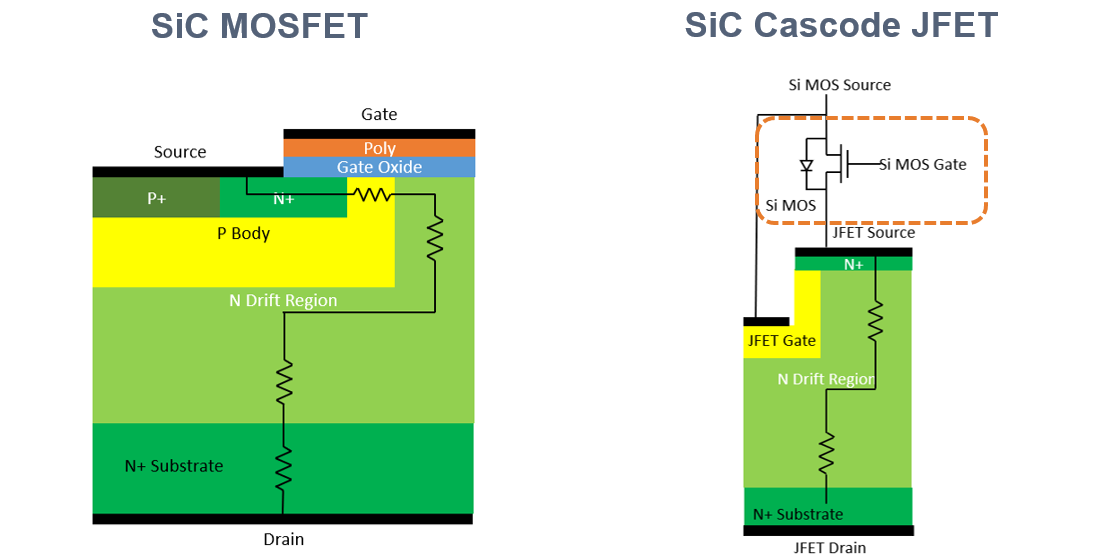

Let’s take a moment to better understand the differences between the SiC MOSFET and the onsemi SiC JFET technologies. In Figure 3 below, we see that SiC MOSFET technology is different from onsemi’s integrated SiC cascode JFET – this is by design. onsemi’s use of a SiC JFET eliminates the need for the SiC MOSFET’s gate oxide layer, which removes the channel resistance and results in a smaller die size.

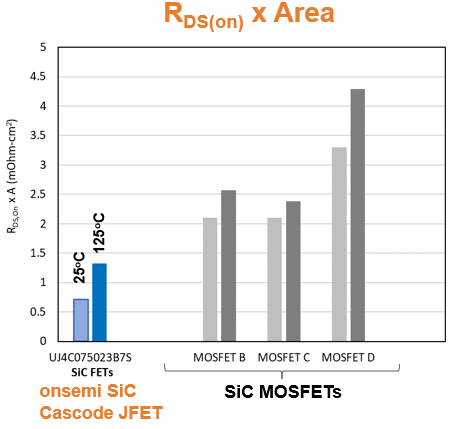

The smaller die size of the onsemi SiC JFET is a key differentiator and is best represented as the ‘RDS(ON) x A’ (RdsA) Figure of Merit (FOM) as shown in Figure 4. This means that the SiC JFET provides a lower on-resistance rating for a given chip size, or said differently, for a given RDS(ON) the onsemi SiC JFET uses a smaller SiC die. onsemi’s industry leadership on the RdsA FOM is reflected in the very low resistance-rated product offerings in relatively small industry-standard packages such as TOLL and D2PAK.

The EliteSiC cascode JFET has lower output capacitance Coss when compared to SiC MOSFETs. Devices with lower output capacitance will switch faster with a low load current and have lower delay times to charge the capacitance. This means smaller, lighter, lower-cost end equipment with increased power density is now possible as there is a reduced need for bulky passive components like inductors and capacitors.

There are other challenges with the SiC MOSFET, such as the following:

- SiC MOS channel resistance is high, causing a lower electron mobility.

- Vth can drift under high Gate bias, meaning the Gate-to-Source voltage drive range is limited.

- The body diode has a high knee voltage, so synchronous rectification is required.

However, these weaknesses disappear using the onsemi SiC JFET because:

- The SiC JFET structure does not have a MOS (metal oxide) structure on the device, so the device is more reliable.

- The Drain to Source resistance is lower for the same chip area.

- The capacitance is lower, equating to faster switching transitions and higher frequency.

Why onsemi EliteSiC Cascode JFETs are Your Choice?

Although there are several SiC power semiconductor choices on the market, some excel more than others in certain applications. One such SiC technology is onsemi’s integrated SiC ‘cascode’ JFET – which finds itself uniquely positioned to provide superior performance due to its low RDS(ON), low output capacitance and high reliability. Besides, the SiC cascode JFET architecture uses standard Si gate drivers, simplifying the transition and enabling implementation in existing designs. Therefore, it offers flexibility for transitioning from Si to SiC—simple implementation—while delivering excellent performance thanks to SiC technology.

These figures of merit help onsemi’s SiC cascode JFET technology excel where others fall short. The added performance of SiC JFET allows it to have higher efficiency in AC-DC power supply units for AI data centers, energy storage, as well DC fast chargers. As higher power density and a compact form factor are demanded, onsemi’s SiC cascode JFETs enable smaller, lighter, and lower-cost end equipment. Increased power density is now possible due to the reduced need for bulky passive components like inductors and capacitors.

Visit our EliteSiC JFET product pages to discover our product offerings.

Read Cascode Primer Operation of the SiC JFET Cascode to learn more about details.

onsemi’s SiC JFET experts will be at APEC2025. Check out the event and attend our sessions to learn more about our technology.