A conversation with Vijay Rentala, CTO of the Analog and Mixed-Signal Group at onsemi.

Q: These are exciting times in the electronics industry, with rapid technological innovation and change. How is that reflected in your approach to product development and significant new launches such as the Treo Platform?

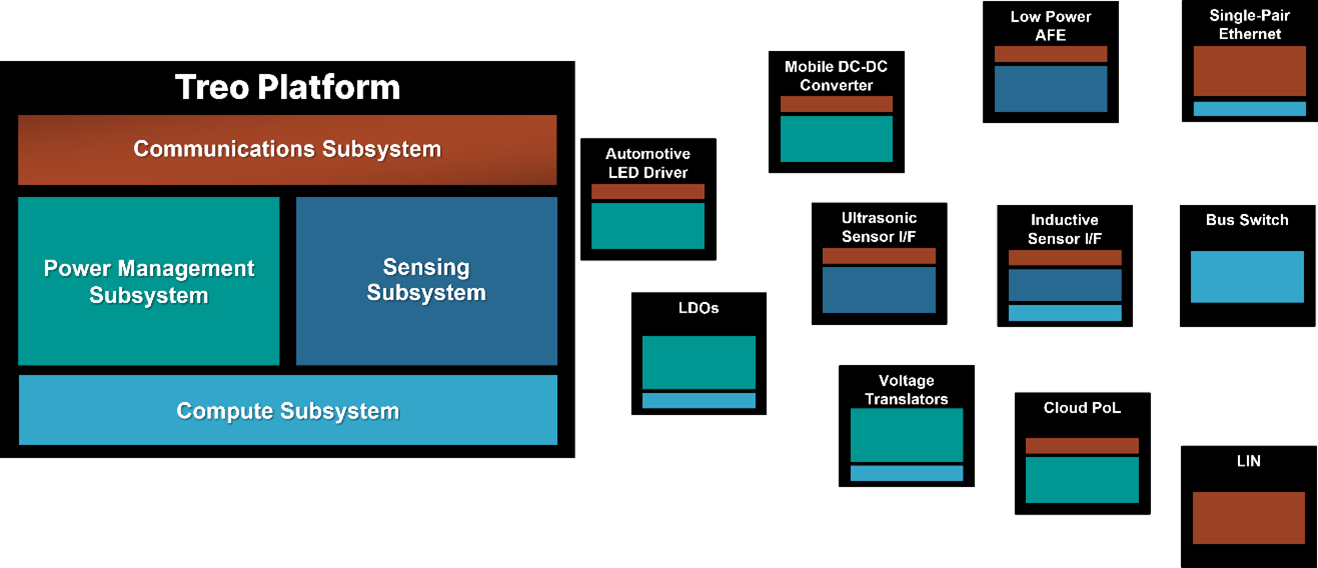

A: Technology never stands still, and at onsemi we constantly strive to innovate and better meet the needs of our customers. That explains why our new Treo modular platform is so exciting. It marks a notable departure from traditional product approaches, with a unified technology platform that integrates intelligent sensing and power. This adaptability will serve a broad spectrum of industries and applications.

Q: That does sound like an interesting new approach with Treo. How does it differ from onsemi’s existing solutions, and what are the key technological advancements introduced?

A: Absolutely, let’s take a deeper dive into the Treo Analog and Mixed-Signal Platform. It is an integrated technology platform combining bipolar, CMOS and DMOS (BCD) transistors within a 65nm process technology. This enables advanced digital processing, high-performance analog and high voltage power delivery in a single integrated circuit, qualified up to 175oC operating temperatures. We believe it represents the most advanced BCD platform solution on the market, designed from day one to meet the strict reliability standards of the automotive industry.

The platform depends on new intellectual property (IP) in the form of reusable design modules or blocks (analog, digital or power IP). They can be combined in nearly endless configurations to develop new products. This modularity simplifies our design process, enabling faster product development while maintaining high integration and quality.

Q: For electronic engineers, efficiency and packaging are often critical design factors. How does Treo’s 65 nm BCD process contribute to improved efficiency and system miniaturization?

A: There is no doubt that the Treo Platform takes miniaturization to the next level, transitioning from system-level integration to chip-level integration, with the platform enabling precise analog control, high-speed digital processing and efficient power handling. This integration minimizes power losses, contributing to more efficient thermal management.

It also shifts the task of integration from the engineer into the platform’s development, with Treo-based products able to push design integration further than most non-BCD equivalents. In addition, compared to physically larger BCD processes, the 65 nm design allows for smaller transistors, reducing power consumption and component size. So, efficiency and packaging have been well considered.

Q: Let’s look at what this could all mean at a practical level. What will be the first products based on the platform, and how will these leverage Treo to benefit the final application?

A: The first products built on the Treo Platform are designed to illustrate its versatility, with some leveraging upwards of ten IP blocks for enhanced functionality, while others focus on size and integration by using only a few IP blocks. Initial solution samples include ultrasonic sensors, logic translators and single-pair Ethernet controller.

One example is the T30LMXT3V4T245 logic level translator. Using BCD technology, it goes beyond the performance of existing level translators, achieving a peak data rate of 400 Mbps, while ensuring superior signal integrity and a high thermal tolerance. This makes it effective for high-speed systems like industrial automation and automotive ADAS, where there is a shift to higher-speed Gigabit ethernet networks and where reliable logic level translation is critical.

The Treo Platform’s roadmap also includes sensor interfaces, PMICs, and advanced applications like solutions for 48V power distribution systems, which will further push the boundaries of energy efficiency and integration. The platform will help engineers develop next-generation products across industries ranging from automotive and industrial to medical wearables and smart home devices.

Q: That presents an exciting vision of future product development. As a follow-up, what impact do you think Treo’s modular design will have on the product development cycle, and are there any specific advantages compared to other competing BCD platforms?

A: One of the core strengths of a modular platform with reusable building blocks in analog, digital and power domains is that it can enable the development of new products that can cater to changing market requirements without redesigning fundamental elements. To realize this benefit, however, the building blocks must be high quality from day one. Attempting to enhance the performance of a modular platform over time can lead to manufacturing issues or compatibility problems with the building blocks.

With Treo, we ensured we had many robust modules that could all work together from inception. This means automotive qualification, high operating temperatures, and a 1-90V voltage range to ensure the platform can meet the demands of everything from consumer mobile devices to industrial and automotive systems.

Of course, BCD and modular platforms are not new concepts, but with Treo, we wanted to create something that had never been seen before. The smaller 65nm is one of the more obvious advantages over existing BCD platforms on the market, but the performance and the breadth of the modules are also crucial. Treo includes analog, digital, mixed signal and power dedicated modules and includes functional elements such as Op-Amps and Low Noise Amplifiers (LNAs), digital signal processing (DSP), memory blocks, sensor interfaces, DC-DC converters and more.

Our product development process is accelerated by a modular design approach, wherein all blocks are compatible and can meet automotive qualification. New Treo products can use just a couple of pre-qualified IP blocks or more than ten; either way, the need for repetitive design verification and qualification is reduced.

Q: Sustainability is becoming a more important factor across electronics. What measures has onsemi taken to ensure the reliability and longevity of the Treo Platform?

Typically, the electronics industry starts with consumer markets and then moves on to automotive, requiring more stringent performance. Instead, all Treo IP blocks are designed for grade 0 automotive qualification. This enables them to function at temperatures as high as 175°C, while specific modules can withstand temperatures up to 200°C. It also makes building automotive-qualified devices incredibly simple; we bring together the IP, and the device is essentially ready for market.

The Treo Platform’s design emphasizes efficient power handling and precise voltage control, while managing parasitic effects through a layout that regulates resistive and capacitive components. It features enhanced isolation techniques through its advanced architecture that provides reduced electromagnetic interference and improved reliability. The groundbreaking deep trench isolation facilitates the symmetrical +/- 1 to 90V operation. These factors contribute to the platform’s reliability and ensure that Treo-based products can withstand harsh conditions over extended life cycles.

Q: Thank you, Vijay, for providing a detailed overview of Treo and its technological advancements. Now for the crystal ball. How will the Treo Platform influence onsemi’s future product development, and what implications does this have for engineers using these products?

The adaptability of the Treo Platform will serve as the foundation for onsemi products for at least the next decade, and potentially even longer, helping to increase the performance and intelligence of our products to match the market’s needs. During that period, it will allow us to deliver more integrated and higher performing solutions faster, helping us and our customers to keep pace with ever-changing market demands.

The platform’s ability to provide more comprehensive and smaller solutions will help to remove integration tasks, lower design efforts, and reduce bill of material component count. It will empower engineers to develop cutting-edge solutions that bring new levels of integration, intelligence, and performance to applications ranging from autonomous vehicles and industrial automation to edge AI data centers and 5G.

In conclusion, Treo’s unique adaptability means it could address up to 70% of all automotive, industrial and medical applications on the market. It is a versatile and scalable solution that will help engineers create the exciting innovations of tomorrow.

For further information on the Treo Platform and to explore how onsemi’s products based on the BCD technology can impact your applications, visit onsemi.com/Treo or request samples.