The ongoing search for efficiency is impacting the design of electronic applications across multiple sectors, including both the automotive and renewables industries. Greater efficiency for an Electric Vehicle (EV) translates into increased range between battery charges and, in renewables, more efficient generation converts more natural energy from the sun or wind into usable electricity.

Both applications use switching electronic devices extensively, and the drive for increased efficiency is driving demand for higher voltage devices. The link between higher voltage and higher efficiency is governed by Ohm’s Law, which states that power, or loss, generated in a circuit increases with the square of the current. The same law also tells us that doubling the voltage halves the current flowing in the circuit – reducing losses by a factor of four. Electricity companies demonstrate this principle, operating their grids at very high voltages – 275,000 or 400,000 volts in the UK – to reduce transmission losses.

While the electricity utilities rely on components such as heavy-duty transformers to handle high transmission voltages, it’s a bit more complicated in automotive and renewables applications, both of which make extensive use of electronic devices.

High Voltage Challenges for Semiconductors

Converters and inverters, based on switching power electronic devices, are key components in both alternative energy plants and EVs. Although both MOSFETs and IGBTs are used in these systems, the low gate-drive power, fast switching speeds and high efficiency at low voltages of the MOSFET have led to its dominance, and it is deployed in a wide range of power electronic applications.

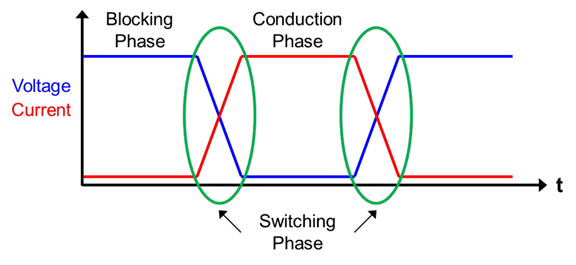

Power MOSFETs have three main roles – blocking, switching, and conducting, figure 2, and the device must meet the requirements of each phase.

During the blocking phase the MOSFET must withstand the full rated voltage of the application, while during the conduction and switching phases, losses and switching frequency are important. Conduction and switching losses both impact overall efficiency while higher switching frequencies enable smaller and lighter systems, a key attribute in both EVs and industrial applications.

The trend towards higher voltage is pushing the limits of the traditional silicon MOSFET. However, it is harder and costlier to get the low RDS(on) and high gate charge values required for reduced conduction losses and fast switching times. Power electronics designers are consequently turning to silicon carbide (SiC) to achieve higher efficiencies. SiC, a wide bandgap technology, has several advantages over silicon, including high thermal conductivity, a low thermal expansion coefficient, and high maximum current density, giving it excellent electrical conductivity compared to silicon. Additionally, SiC’s higher critical breakdown field means that a reduced thickness device can support a given voltage rating, leading to significant size reduction.

SiC MOSFETs are now available which can withstand voltage thresholds up to almost 10 kV, compared with 1500 V for the silicon variants. Also, the low switching losses and high operating frequencies of SiC devices enable them to achieve superior efficiencies, particularly in higher-power applications requiring high current, high temperatures, and high thermal conductivity.

onsemi Addresses the Need for Higher Voltages

In response to the growing demand for devices with high breakdown voltages, onsemi has built an end-to-end in-house SiC manufacturing capability including a range of products such as SiC diodes, SiC MOSFETs, and SiC modules.

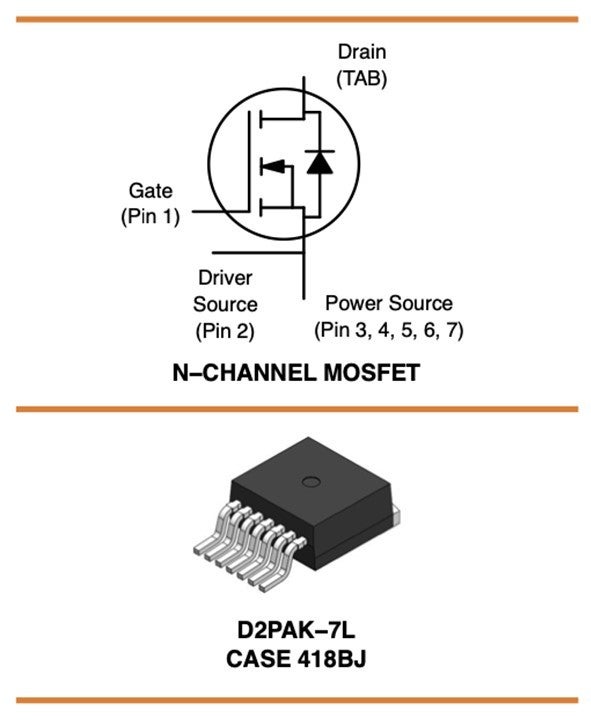

This product family includes the NTBG028N170M1, a high-breakdown voltage SiC MOSFET, figure 3. This N-channel, planar device is optimized for fast switching applications at high voltages, with a VDSS of 1700 V, and an extended VGS of ‑15/+25 V.

The NTBG028N170M1 supports drain currents (ID) up to 71 A continuously and 195 A when pulsed and its superior RDS(ON) – typical value 28 mW - mitigates conduction losses. The ultra-low gate charge (QG(tot)), at just 222 nC, ensures low losses during high-frequency operation and the device is housed in a surface mountable D2PAK–7L package, which reduces parasitic effects during operation.

The onsemi EliteSiC range also includes a range of 1700 V-rated SiC Schottky diodes, which complement MOSFETs in power electronics systems such as rectifiers. The high Maximum Repetitive Peak Reverse Voltage (VRRM) of these diodes, along with their low Peak Forward voltage, (VFM) and excellent reverse leakage currents, equip design engineers to achieve stable, high voltage operation at elevated temperatures.

EliteSiC Supports Efficient Power Electronics Designs

The quest for efficiency is relentless in applications which depend on power electronics devices. The trend towards higher system voltages is challenging the traditional Si-MOSFET and SiC devices offer a way forward, enhancing efficiencies while reducing form factors. The 1700 V NTBG028N170M1 from onsemi enables higher voltage designs for key power electronics systems.

Learn more about EliteSiC technologies.