There is a huge shift towards electrification, especially in transportation and infrastructure. All manner of vehicles including passenger cars and commercial/agricultural vehicles (CAVs) are moving to electric propulsion. According to the IEA in 2022, the 1300TWh of renewable electricity generated by solar surpassed wind power for the first time.

Inverters and converters are required to transform energy. Solar photovoltaic (PV) panels generate DC while power grids operate on AC. A similar situation exists as the traction battery system in electric vehicles (EVs) is DC. Here the traction motors in engines require AC.

In both cases, the efficiency of power conversion process is critical as any losses manifest as heat, which ultimately leads to a larger solution through the need for thermal mitigation such as fans or heatsinks. Size and weight are important to achieve smaller footprint in given power level.

IGBT-based modules are widely used for power conversion applications and selecting the right module will determine overall system performance. Learn more about the latest half-bridge IGBT modules. Join our exclusive webinar covering our latest Field Stop 7 (FS7) IGBT based QDual3 Modules.

Finding a Right Topology

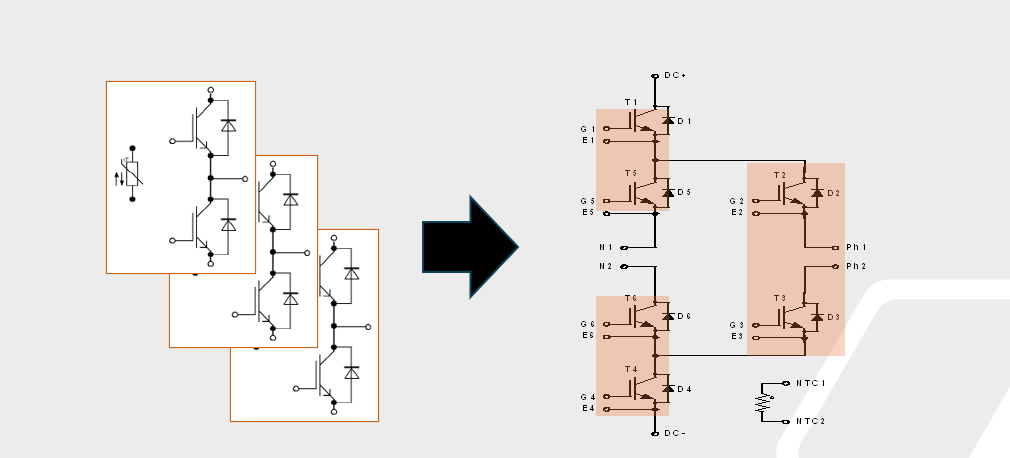

Choosing the best circuit configuration is essential to obtaining the best efficiency. Solar inverter and battery energy storage inverters commonly use a 3-level active neutral point clamped (ANPC) converter as this topology is designed for enhanced performance and efficiency. As Figure 1 depicts, three half-bridge modules could be connected to form ANPC topology, which popularly uses high power IGBT switches to improve control and reduce losses. The topology also reduces voltage stress on individual components, thereby improving reliability.

By paralleling multiple QDual 3 IGBT modules from onsemi, design engineers can create high-performance three-level ANPC converter capable of delivering 1.6 to 1.8 MW of power output.

onsemi’s New Higher Power QDual3 Technology

The underlying technology used for the switches in the QDual 3 module has a significant impact on performance and efficiency. The modules are based on the latest Field Stop 7 (FS7) IGBT technology which delivers the highest levels of performance in high-power applications including solar inverters, energy storage, and CAVs. This is largely due to the key parameter VCE(SAT) having been improved by 0.4V compared to our previous generation of IGBTs.

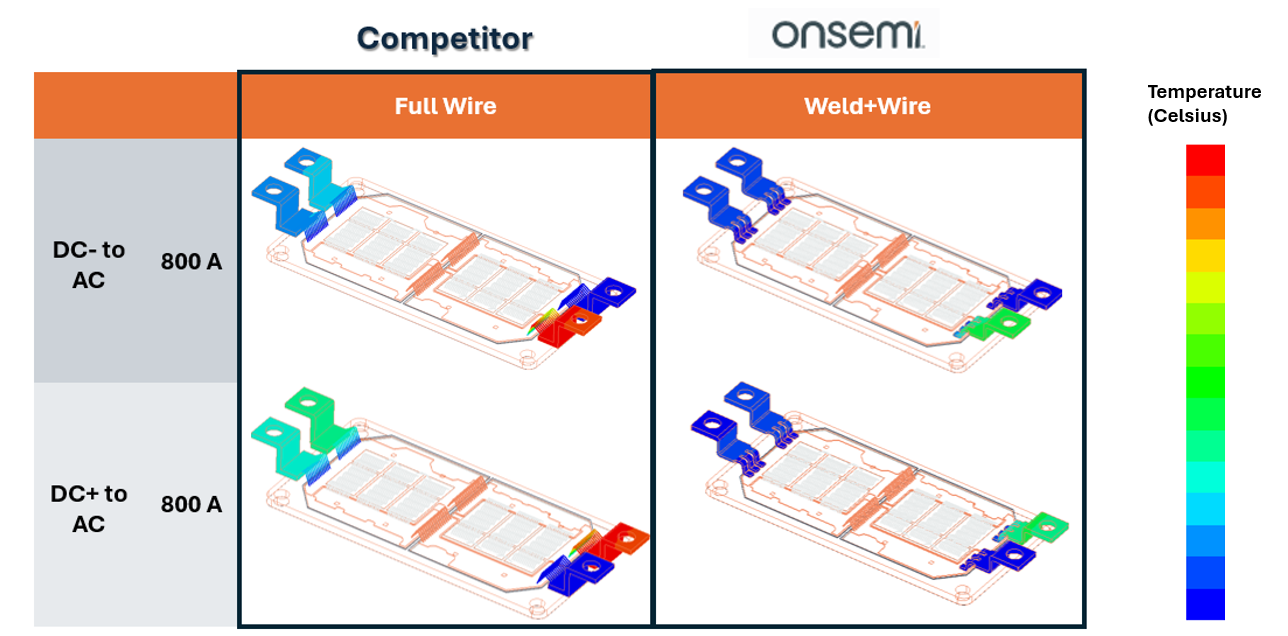

FS7 technology also shrinks the chip size by around 30% from its predecessor. Combining increased chip power density with other packaging enhancements such as maximized conducting trace width and power terminal design, allows for QDual3 to carry higher current from the latest generation IGBT power modules.

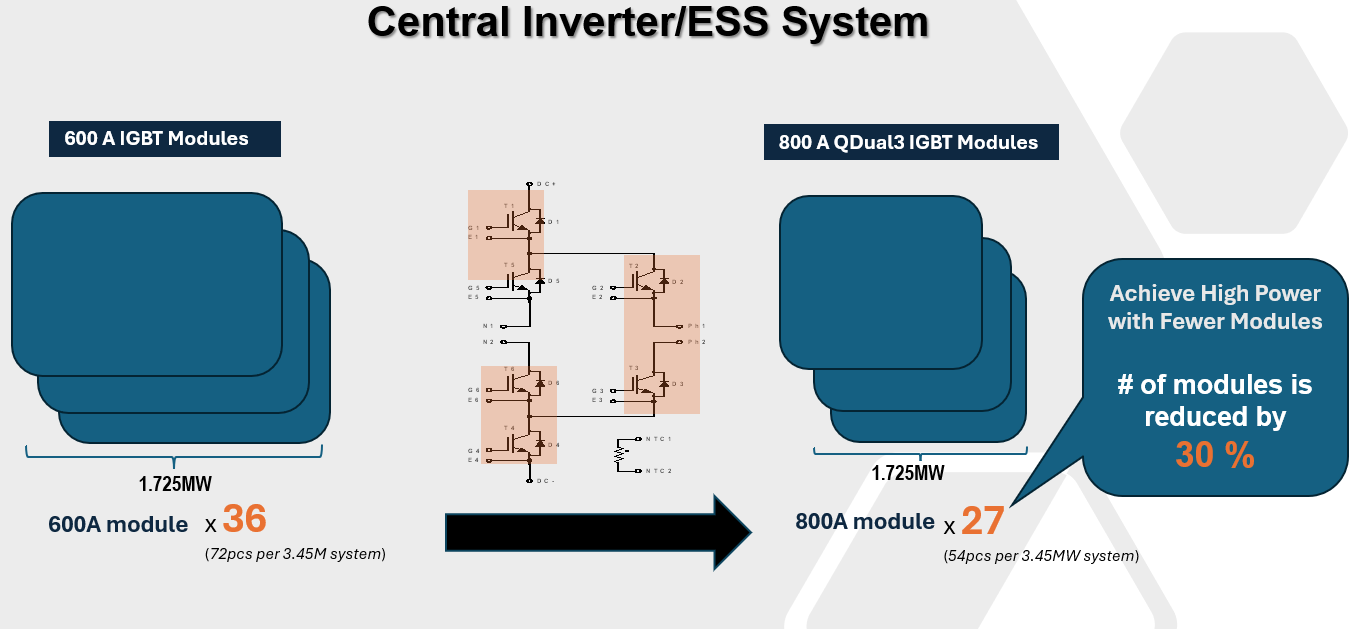

Compared to previous 600A modules under the same outline and footprint, the Qdual3 solutions offer 33% more current capability (800A). With a 600A module, a total of 36 modules would have to be combined to create an ANPC 1.725MW inverter. However, with the higher 800A rating of the Qdual3 modules, fewer modules are needed and the 1.725MW inverter requires just 27 modules. Nine fewer modules represent a 25% saving in size, weight, and reduce system cost in control.

QDual3 is also popularly used in commercial and agricultural vehicles motor drive. The overall vehicle could achieve higher power with less paralleling and efficiency enhancement. All these can contribute to the vehicle’s range and simpler system design.

Every module incorporates an isolated baseplate for mounting and thermal management. Direct PCB mounting is possible using the solderable pins which are configured in an industry-standard layout pattern. This allows for multi-sourcing as well as giving the ability to retrofit the units to existing designs, permitting them to benefit from the latest technology.

With reliability being crucial, all QDual3 modules are subjected to onsemi’s stringent reliability testing that exceeds testing completed on other comparable devices on the market. Humidity testing is performed with a 960V bias for 2000 hours compared to 80V for 1000 hours for competitive devices. Vibration testing (which is essential for CAV applications) is performed at 10G RMS for 22 hours to meet AQG324 – much more than the 5G / 1 hour used elsewhere.

Join our upcoming webinar and explore how QDual 3 modules provide enhanced efficiency, cost reductions, and design simplicity.

More Information:

Product Page: NXH800H120L7QDSG, SNXH800H120L7QDSG

Data Sheet: NXH800H120L7QDSG, SNXH800H120LQDSG

Solution guides: Battery Energy Storage System

Video: Latest onsemi 7th Gen QDual3 IGBT Modules Simplify Design and Reduce Costs