While three-phase permanent magnet brushless DC (BLDC) motors require an electronic commutation circuit for control, conventional brushed DC motors are mechanically self-commutating. Unlike brushed DC motors, BLDC motors do not have brushes requiring periodic maintenance or replacement, making them less susceptible to wear and tear. We’ll briefly look at BLDC motor construction and control. Then, we’ll introduce the three commutation methods:

Finally, we’ll propose an innovative approach to BLDC commutation that implements all three commutation methods in a single motor controller integrated circuit (IC).

BLDC Construction

The BLDC motor is a rotating electric motor with three-phase armature windings on the stator and permanent magnets on the rotor—the inverse of the brushed DC motor with the stator containing the permanent magnets. The magnets on the BLDC motor rotor provide a constant magnetic field that enables a highly efficient, high-torque motor with low moment-of-inertia. Three-phase BLDC motor control design can implement a commutation circuit with discrete components or a dedicated control IC with an integrated power module. Through downsized PCB area and manufacturing steps, the integrated solution reduces overall system cost and increases solution reliability. It minimizes BOM, reduces inventory costs, and promotes rapid reuse of solution derivatives in new inverter designs.

BLDC Control

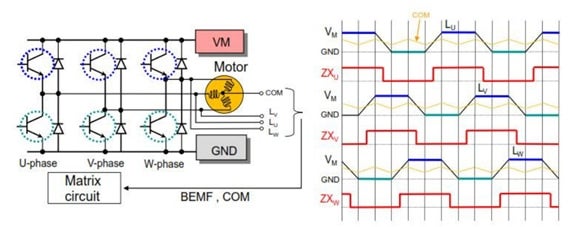

A power stage with a three-phase full-bridge scheme and a controller make up a typical three-phase BLDC motor drive. These provide a three-phase pulse width modulation (PWM) signal based on three Hall-effect sensors—or an encoder to provide position feedback for sensored operation or sensing of back-EMF signals for sensorless operation. The stator winding of a BLDC motor generates a back-EMF waveform with a trapezoidal shape.

An electronic commutation control circuit determines the position and speed of the BLDC motor using six-step trapezoidal and field-oriented control (FOC), also called vector control, commutation methods. Both Hall-effect sensors and back-EMF sensing provide a cost-effective way to perform rotor position sensing.

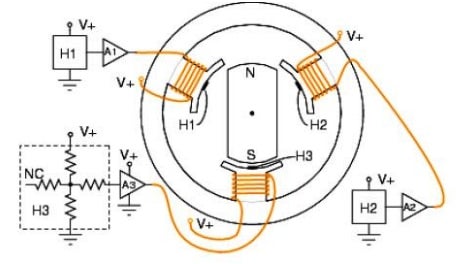

Figure 1 BLDC Hall Snsor Locations (https://www.onsemi.com/pub/collateral/tnd6041-d.pdf)

Trapezoidal Commutation

Six-step trapezoidal commutation, popular because of the simplicity of the control algorithm, uses two power switch devices, following a predetermined sequence, on each motor phase. Three Hall-effect sensors provide rotor position information and are very effective at controlling motor speed. The six-step switching sequence is determined to conduct two consecutive motor phases (with a 60° interval) as the motor spins.

Figure 2 6-step Trapezoidal Control Waveforms (https://www.onsemi.com/pub/collateral/tnd6041-d.pdf)

Field Oriented Control

More suitable for higher-end applications is sensored or sensorless FOC, a more complex commutation method with higher processing requirements. The voltage and current vectors calculated based on motor current feedback commutate the motor enabling precise dynamic control of both speed and torque that maintains high efficiency over a wide operating range.

Direct Torque and Flux Control

DTFC is a new unique, more efficient approach to sensorless BLDC commutation developed through joint collaboration between onsemi and Theta Power Solutions, Intl (TPSI). The method provides flux-weakening extended high-speed capability for BLDC motors operating with heavy loads at low speeds with minimum torque ripple—ideal for braking algorithms to provide controlled deceleration with high inertial loads.

3-in-1 Choice of Control

The EcoSpin™ family of configurable motor controllers from onsemi provides a choice of all three BLDC control methods. The ECS640A is a System-in-Package (SiP) solution, integrating an Arm® Cortex®−M0+ microcontroller, three sense amplifiers, a reference amplifier, three bootstrap diodes, and a high-voltage gate driver designed for high-speed operation. It drives MOSFETs and IGBTs operating up to 600 V (FAN73896) with six gate driver outputs to sink or source 350 mA/650 mA (typical) gate current to external power devices and includes Hall Sensor inputs to support sensored or sensorless operation. This device is ideal for use with discrete power devices to maximize scalability due to its small footprint and integration flexibility.

Motor control system designers will like that the integrated solution makes the system easy to set up quickly, rather than getting lost in the details of spinning the motor, with an easy-to-use graphical user interface that simplifies code development and reduces time-to-market.

Flexibility and Integration

Fully exploiting the advantages of increasingly popular BLDC motors requires implementing the ideal commutation method. Selecting a BLDC motor controller IC that offers the widest number of commutation options with high integration makes the most sense. The onsemi ECS640A motor controller provides this flexibility for sensored and sensorless applications, including white goods, refrigeration compressors and blowers, bottle coolers, HVAC blowers and condensers, pool pumps, industrial drives and pumps, and robotics.

Learn more about the ECS640A motor controller and other motor control solutions from onsemi.