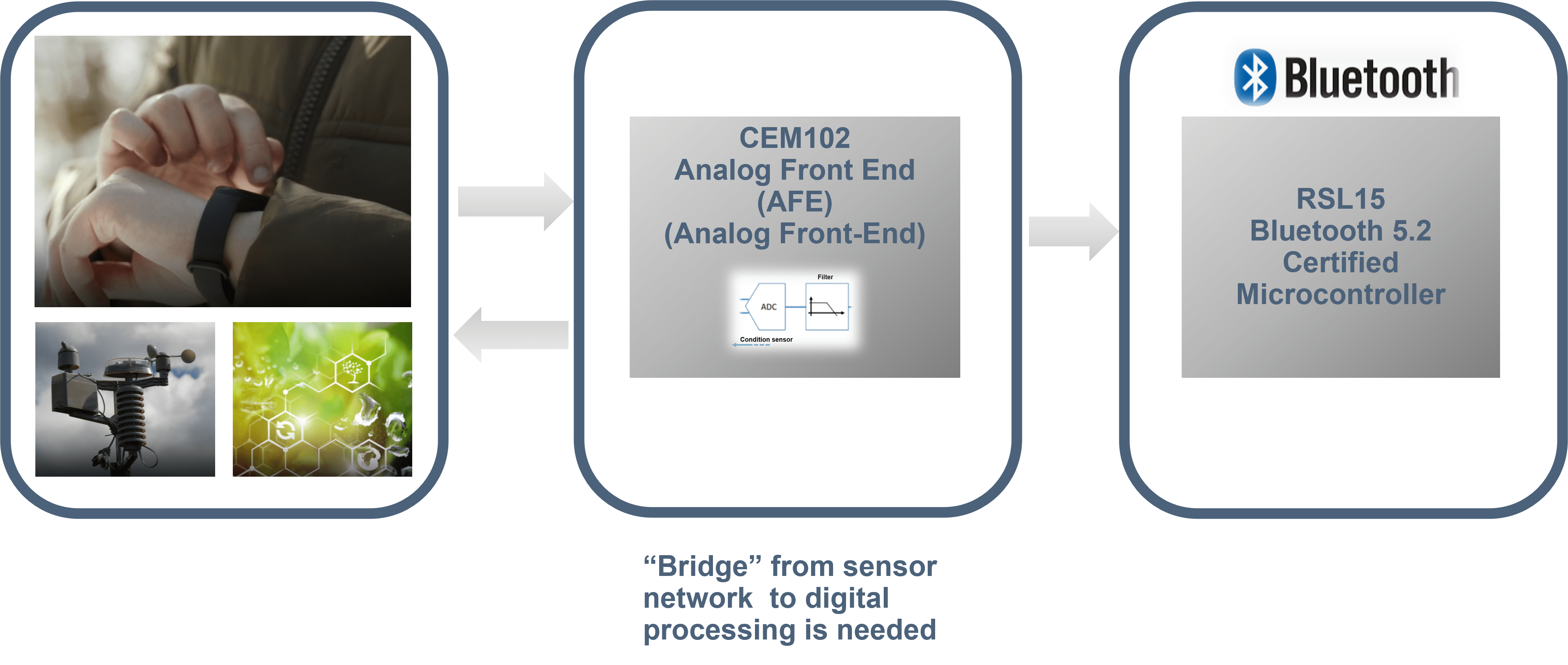

In today’s advanced technological era, the prevalence and importance of electrochemical sensors is growing rapidly. Quantifying chemicals improves safety, efficiency and awareness in diverse fields such as medical and environmental sciences, and industrial material and food processing. When you combine this sensing capability with a low power consumption analog front-end (AFE) device and Bluetooth® Low Energy technology, it can further enhance the effectiveness of these solutions.

Interconnected electrochemical sensors have the potential to advance scientific understanding and enhance our quality of life. Solutions such as wearable devices that monitor glucose levels for individuals with diabetes, gas detectors used to evaluate environmental contaminants, histamine sensors for improving food safety, or industrial potentiostat or corrosion sensors all play a vital role in the modern world.

Inside an Electrochemical Sensor

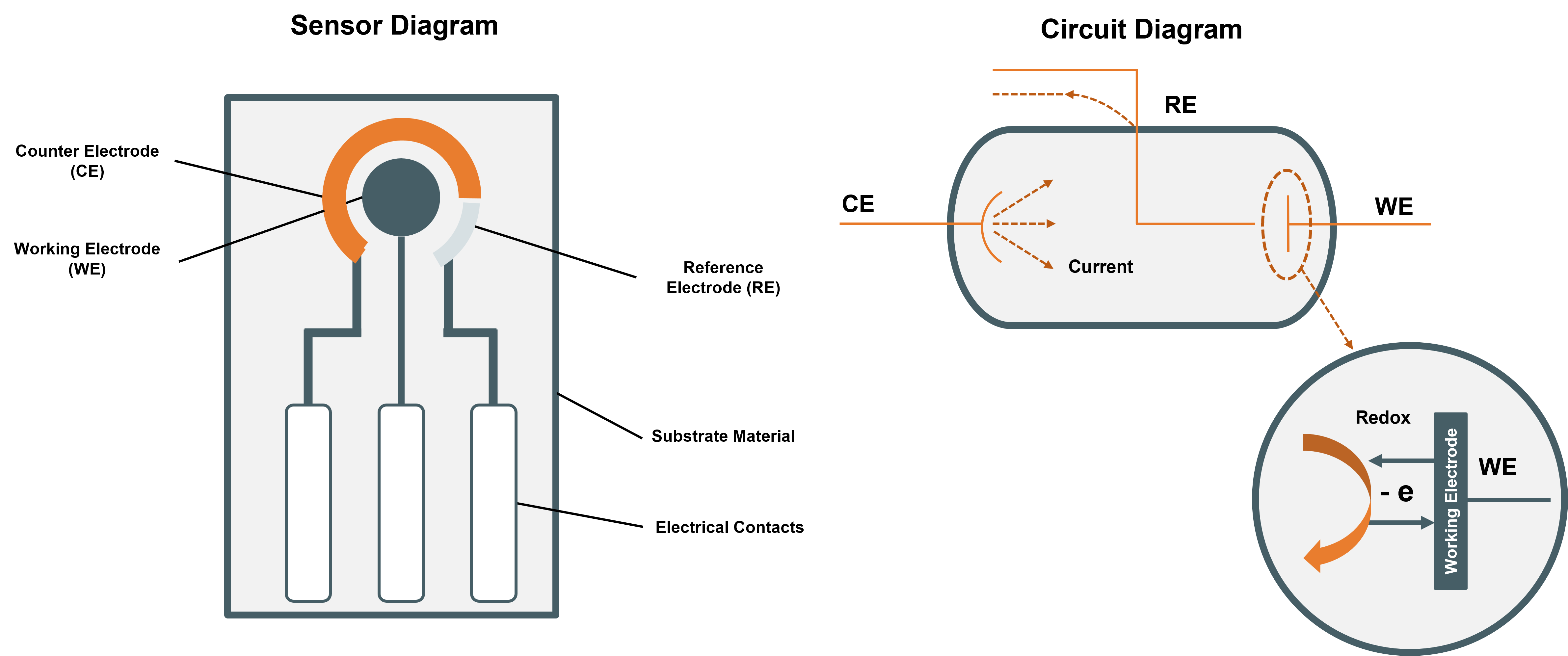

The typical setup for an electrochemical sensor in electronic engineering involves a three-electrode system (Figure 2).

At the core of the sensor are three main parts (Figure 2). The working electrode (WE) is where the electrochemical reaction occurs, resulting in electron flow and current production. The counter electrode (CE) balances redox reactions at the WE for accurate sensing, while the reference electrode (RE) measures WE potential and provides feedback for the CE voltage.

Finally, the current produced by the WE is converted into a voltage. With additional digital processing and wireless communication, it is possible to build powerful connected solutions that can provide insight into the environment around us as well as our own bodies.

Electrochemical Measurement Applications

Electrochemical sensors are vital in many remote patient monitoring applications, such as continuous glucose monitoring (CGM) – a critical component in the management of diabetes, a chronic illness that affects 1 in 11 people worldwide[1]. The CGM device market is projected to grow at a compound annual growth rate (CAGR) of 9% from 2023 to 2032[2].

In environmental settings, including air pollution/quality measurement, electrochemical sensors are used for detecting gases including carbon monoxide, hydrogen sulfide and oxides of nitrogen and sulfur. While in food production, handheld portable devices and larger automated electrochemical detection solutions are used to ensure both taste and the absence of allergens or hazardous chemicals.

The precise measurement enabled by an AFE device, paired with an electrochemical sensor, is critical not just for healthcare and industrial processes, but also helps us advance scientific knowledge. For example, wearable or portable medical devices allow continuous remote monitoring of glucose levels, providing researchers with unprecedented insight which can accelerate innovation and benefit the global population.

onsemi’s Solutions for Electrochemical Measurement

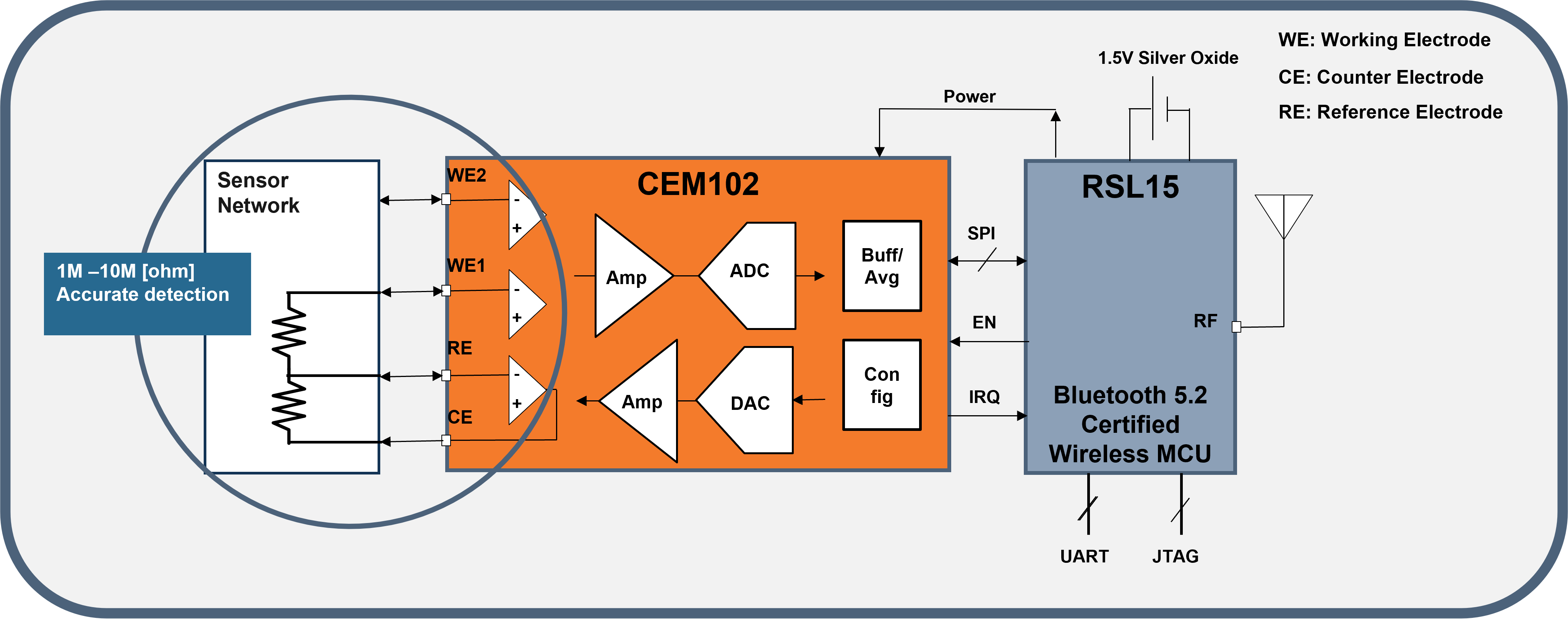

onsemi recently announced the availability of the CEM102- a state-of-the-art miniaturized AFE designed to accurately measure electrochemical and amperometric currents. The CEM102 is designed to pair with the RSL15 Bluetooth 5.2 certified wireless microcontroller, which provides the industry’s lowest power secure Bluetooth Low Energy technology. Together, this solution allows designers to develop extremely accurate, low power and compact sensing applications.

onsemi’s CEM102 + RSL15 solution offers improved precision, reduced noise and lower power usage in comparison to individual solutions. It allows for a simplified bill of materials (BoM) and provides more flexibility in configuration, ultimately freeing up development resources. Importantly, this flexibility makes it a solution not only for measuring electrochemical based sensors, but for many types of sensors where small current needs to be accurately measured.

The CEM102 + RSL15 platform supports two battery selections of 1.3 - 1.65 V and 2.375 - 3.6V, with the device consuming just 3.5 uA in active measurement mode with the 18-bit ADC continuously converting. This translates to a market-leading 14 days of operation with just a 3 mAh battery.

With its compact 1.884 x 1.848 mm packaging and the ability to operate with one to four electrodes it can help to create smaller and more efficient wearable healthcare solutions, enhancing user experiences.

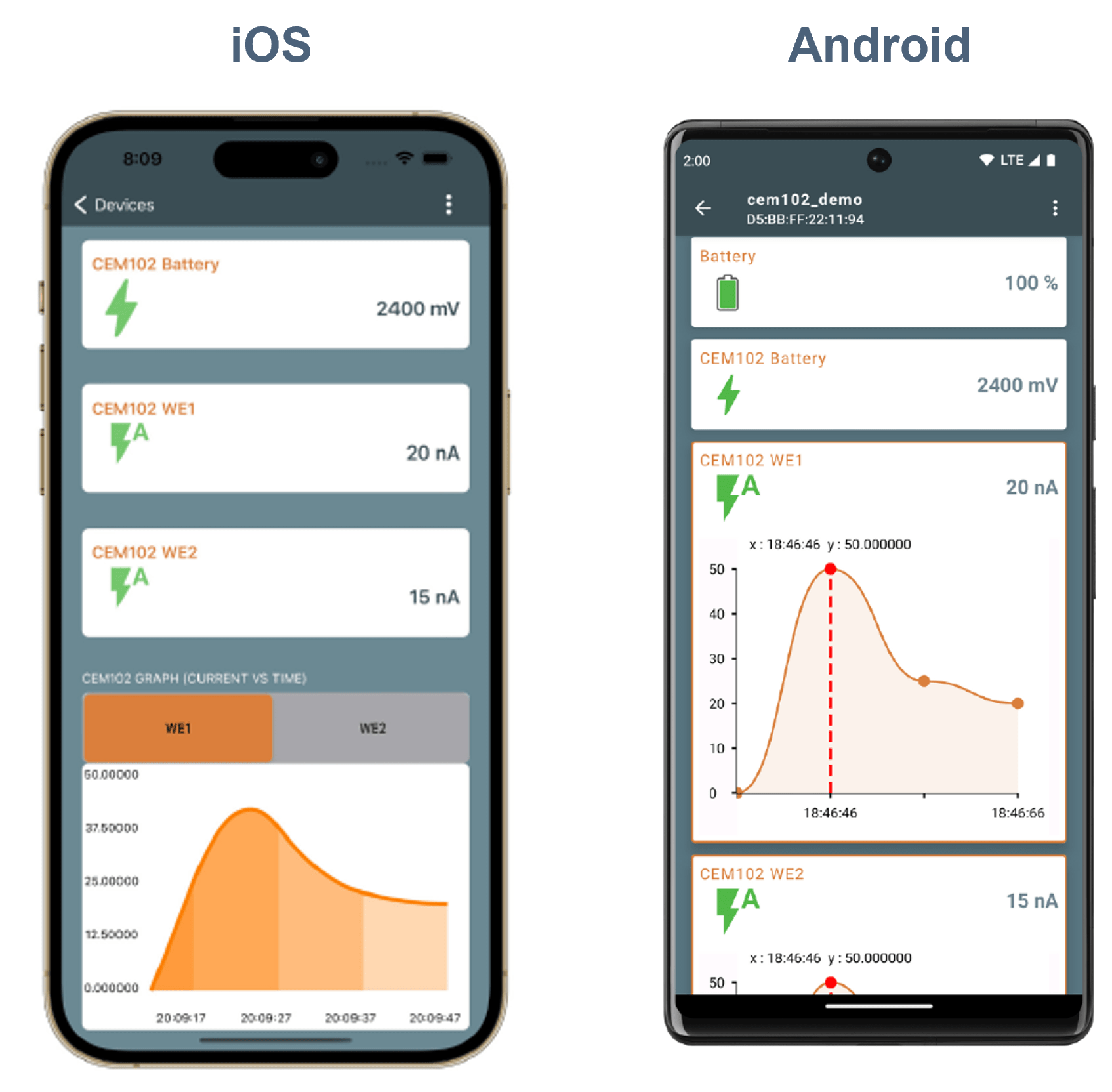

To simplify development, the CEM102 + RSL15 offering facilitates ongoing sensing across multiple sensors through cutting-edge hardware, extensive development support, firmware, software and IOSAndroid™ demo applications (Figure 4).

The accurate detection and measurement of various chemical currents is opening the door to new scientific advancements. With its small form factor and industry’s lowest power consumption, it enables further miniaturization and increase of battery life for all end applications. The solutions afforded by the CEM102 and RSL15 platform aid engineers in creating compact, resilient, and affordable connected products like those used in medical care that enhance glucose regulation, reduce diabetes-related risks and better integrate with our lives.

The use of electrochemical sensors is widespread in healthcare, environmental monitoring, and industrial safety, playing a crucial role in shaping society. The versatility of this technology goes far beyond what is currently being utilized, and cutting-edge platforms like onsemi’s are also essential in furthering scientific research and uncovering new applications.

Learn more about the CEM102, or explore onsemi’s sensing solutions.

[1] https://www.diabetes.co.uk/diabetes-prevalence.html

[2] https://www.precedenceresearch.com/continuous-glucose-monitoring-device-market