At the core of every Machine Vision (MV) system lies the image sensor, a fundamental component translating the physical world into digital data. Image sensors play a pivotal role in ensuring accuracy, reliability, and efficiency in machine vision operations. In this blog post, onsemi explores the critical considerations when selecting image sensors for MV systems, illuminating their significance in driving innovation and progress across diverse sectors.

Physical Considerations

As the backbone of machine vision image sensors need to have optimized physical characteristics to enhance the system’s performance and effectiveness. What are these critical physical characteristics that should be factored in when selecting sensors?

Resolution

The resolution of an image sensor determines its ability to capture fine details in the visual data. Optimal resolution, or in other words the number of pixels in both vertical and horizontal direction, is essential for ensuring accurate analysis and decision-making in machine vision applications. However, striking the right balance is crucial, as excessively high resolution can lead to unnecessary costs without providing significant benefits while a low resolution may lead to missing specific details or information once is looking for. It’s essential to assess the specific requirements of the application and select a resolution that aligns with the desired level of detail.

Optical Format

The optical format of an image sensor refers to the size and shape of its light-sensitive area. Sensor size affects several aspects of imaging performance, including field of view, depth of field and light sensitivity, which is the most important factor when selecting a sensor for use in low-light conditions and can ensure a cleaner result. Larger sensors generally provide better image quality but can also make the camera system bulkier and more expensive. Matching the optical format with the lens’ projection ensures efficient utilization of the sensor’s resolution. This alignment is crucial for achieving sharp and clear images, especially in applications where precise image quality is paramount. In addition, the optimal resolution will reduce the camera costs as cheaper or more efficient lenses can be used, while at the same time the physical form actor or size of the camera is reduced lowering the cost even further.

Aspect Ratio

The aspect ratio of an image sensor influences the layout of the captured image and the distribution of pixels. Choosing the optimal aspect ratio ensures that you’re able to effectively utilize the sensor’s resolution and that the captured images accurately represent the scene. Examples. include ITS (Intelligent Traffic Systems) or tire inspections where typically larger horizontal resolutions are preferred.

Frame Rate

The frame rate of an image sensor determines the number of images captured per second. In dynamic environments or applications involving moving objects, a high frame rate is essential for accurately capturing and analyzing visual data. This enables the system to “freeze” motion and maintain synchronization with the physical space being imaged, ensuring precise measurements and decision-making. Windowing or the read out of Regions of Interest (ROI) will increase the frame rate as there is less data to be read out. Some sensors will see an advantage when reducing the vertical resolution only, while others may see a benefit in case the resolution in both directions is reduced. Subsampling, or skipping pixels during the read out has a similar effect on the frame rate, but obviously at a loss of resolution in that particular window.

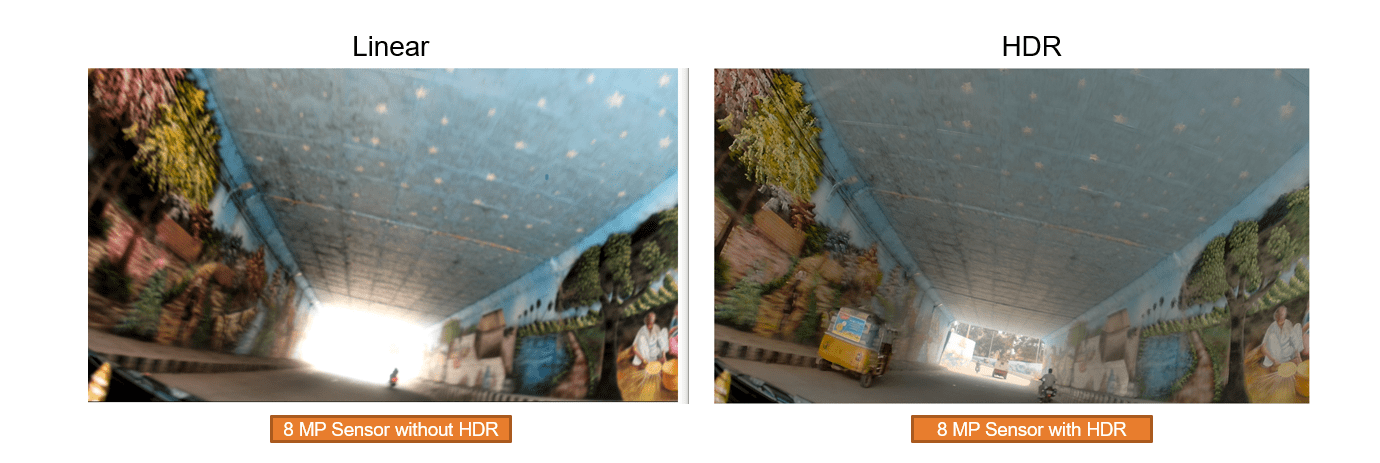

Dynamic Range

Another critical physical consideration for an image sensor is its dynamic range. This refers to the sensor’s ability to capture a wide range of brightness levels in the scene, from the darkest shadows to the brightest highlights. A higher dynamic range ensures that the sensor can accurately reproduce the full range of tones present in the scene in a single frame, resulting in images with enhanced contrast and detail. This capability is crucial in everyday scenarios, such as driving through a tunnel. When a vehicle exits a dark tunnel into bright sunlight, a high dynamic range (HDR) image sensor can simultaneously handle the low light inside the tunnel and the intense brightness outside, ensuring clear visibility of all elements. In machine vision systems, HDR plays an essential role by allowing robots and automated systems to accurately perceive and interpret scenes with stark contrasts. For instance, in industrial settings, HDR-enabled sensors ensure that machines can detect defects on shiny, reflective surfaces or read labels in poorly lit environments. The enhanced detail and accuracy provided by HDR, improve the reliability and efficiency of machine vision applications, contributing to better quality control, automation, and safety in various industries.

Optical Considerations

In addition to physical parameters, the optical characteristics of image sensors are equally crucial in determining the performance and suitability of machine vision systems. Here are the key optical considerations.

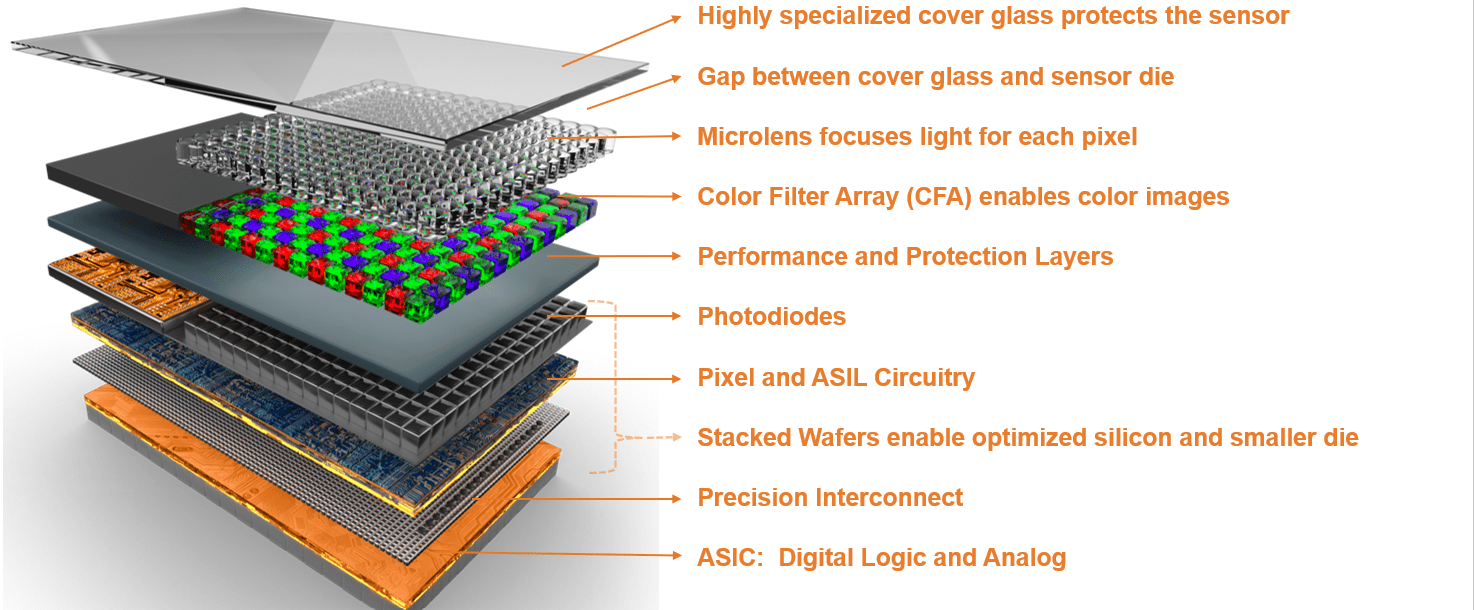

Pixel Considerations

Pixels are the building blocks of image sensors, and their size directly impacts the sensor’s sensitivity to light and its resolution. Larger pixels tend to admit more photons, resulting in improved signal-to-noise ratio and better image quality, especially in low-light conditions.

Larger pixels also require more silicon, leading to increased sensor size and cost. Conversely, smaller pixels enable higher resolution but may require more complex optical designs to achieve comparable image quality. Selecting the right pixel size involves striking a balance between sensitivity, resolution, and cost.

Output Modes

Image sensors often offer various output modes, such as Region of Interest (ROI), binning, or decimation to provide flexibility in data acquisition and processing. ROI allows selective reading of specific areas within the image, enabling faster frame rates and reduced data volume. Binning combines adjacent pixel arrays into one large pixel (e.g., 4 to 1 or 9 to 1) to increase sensitivity or reduce noise, while decimation reduces image resolution to increase processing speed.

These output modes empower users to optimize the sensor’s performance according to the application’s needs, whether it requires high-speed imaging, increased sensitivity, or efficient data management.

Rolling Shutter vs Global Shutter

Choosing between these shutter types depends on motion artifacts and application requirements. These classifications define the shutter mechanism employed by the sensor. Rolling shutter sensors sequentially expose rows of pixels. In contrast, global shutter sensors expose all pixels simultaneously.

Comparing Rolling Shutter and Global Shutter

The choice between rolling shutter and global shutter is a critical decision when selecting image sensors for machine vision applications. Here’s how the two compare.

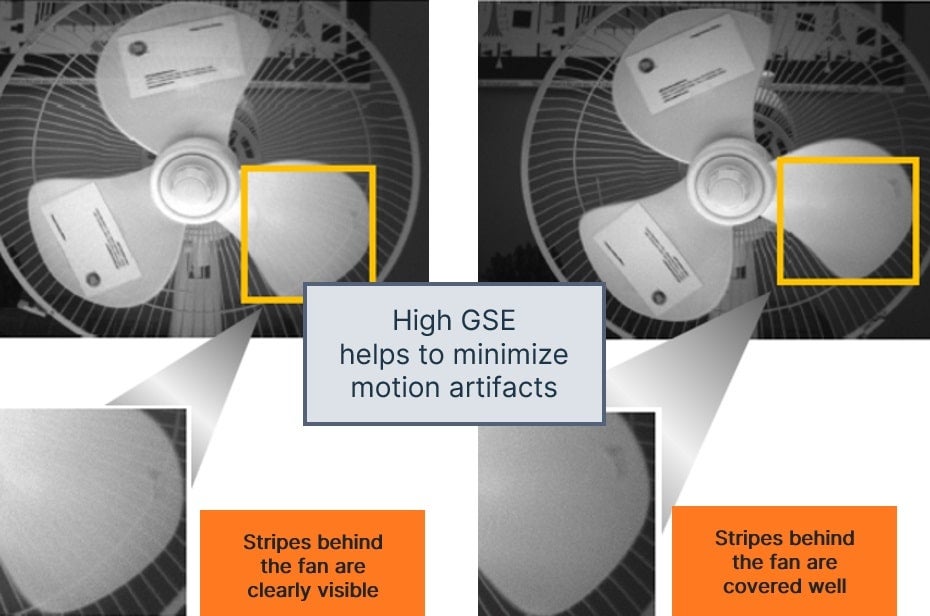

Motion Artifacts

Rolling shutter sensors expose different parts of the image at slightly different times, which can result in motion artifacts like skew or distortion. This problem is especially common when capturing fast-moving objects or scenes with rapid changes. In contrast, global shutter sensors capture the entire image simultaneously, eliminating motion-induced distortions and ensuring consistent exposure.

Global Shutter Efficiency

Global shutter sensors excel in scenarios involving fast-moving objects or dynamic environments as they effectively freeze motion and deliver crisp images. This makes them ideal for applications requiring precise motion analysis or high-speed object tracking.

Features Comparison

An image sensor with a global shutter offers several advantages:

- Minimized motion artifact (caused by either the object/target or camera motion e.g. in case of hand held applications)

- Uniform exposure

- Superior performance in dynamic environments

Additionally, global shutter sensors facilitate efficient motion analysis, enabling accurate tracking and positioning of objects. While rolling shutter sensors may be adequate for stationary or slower-paced applications, global shutter is ideal for more demanding machine vision tasks.

What To Look for in Image Sensors

Choosing the right kind of image sensor for machine vision systems is the key to ensuring efficiency and accuracy. Global shutter image sensors, such as the ones we offer at onsemi, offer a comprehensive solution for machine vision applications. Our sensors address various critical considerations beyond motion capture, featuring high resolution, optimal pixel size, and flexible output modes.

The global shutter also facilitates precise motion capture and analysis. By capturing the entire image simultaneously, global shutter sensors eliminate motion artifacts and ensure uniform exposure, delivering clear and distortion-free images. These features are invaluable in tracking fast-moving objects and ever-changing environments.

With onsemi’s technology, camera manufacturers can achieve optimal results in their machine vision applications.

For more information read our machine visions system solution guide