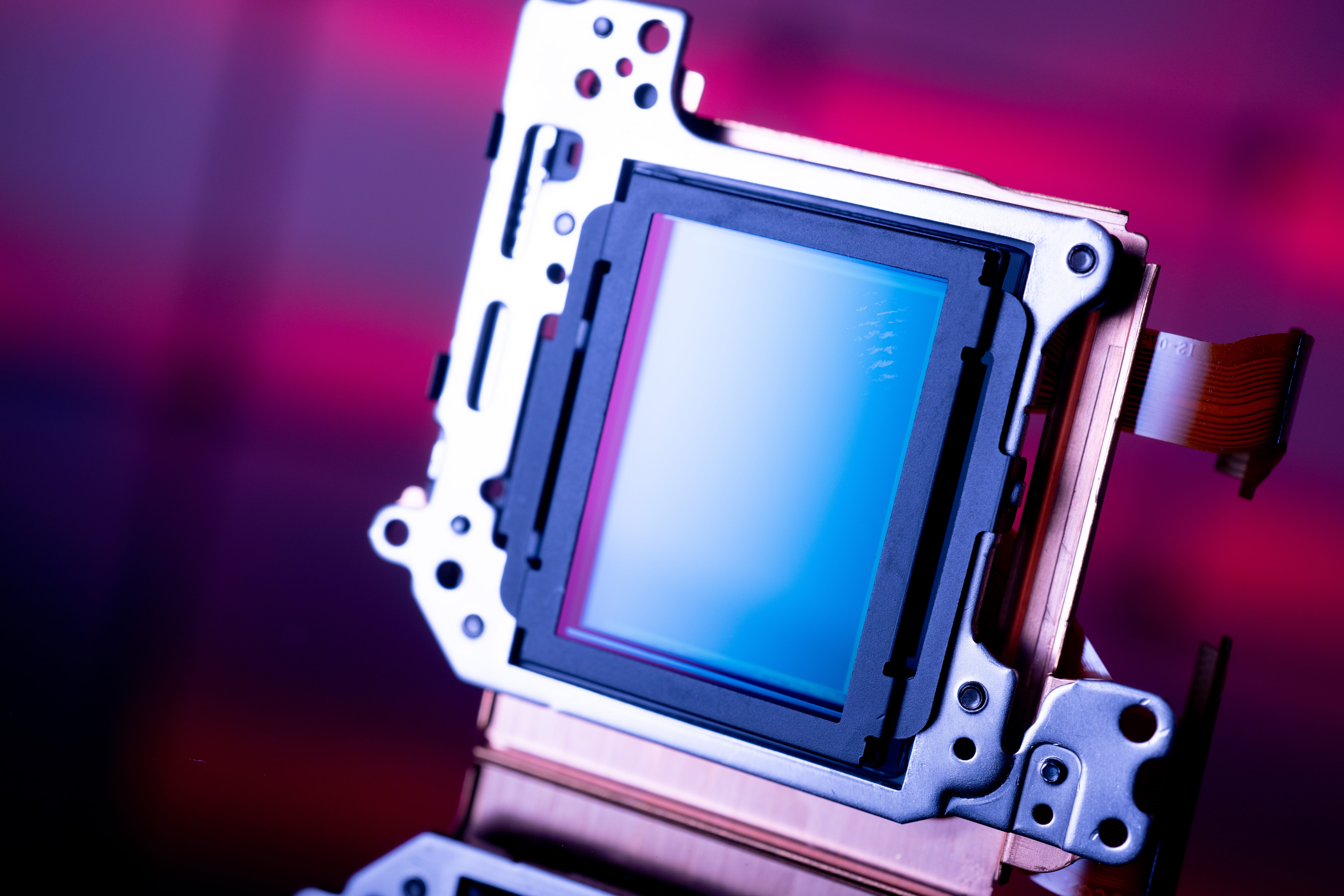

Image sensors have become a crucial component in shaping innovation within the contemporary automotive landscape. These compact yet powerful components serve as the eyes of modern vehicles, enabling advanced driver-assistance systems (ADAS) and enhancing safety features. However, the globalization of supply chains exposes automotive manufacturers to vulnerabilities that can significantly impact the sourcing of image sensors. Obstacles such as climate events, natural disasters, geopolitical shifts, and global health crises are ever-present and unpredictable in nature. Therefore, it’s essential to establish a resilient image sensor supply chain in modern automotive manufacturing.

Understanding the Global Landscape

In order to maintain a competitive edge, automotive manufacturers must ensure a dependable supply chain of crucial components like image sensors. However, there are difficulties that come with managing high-volume component procurement:

- Natural Disasters: Climate events and natural disasters, including floods, fires, and earthquakes, can disrupt both production facilities and shipping routers.

- Global Instability: Changes in the geopolitical landscape, characterized by political instability, conflicts and frequent alterations in trade policies present a threat to both manufacturing and trade routes. In March 2024, container shipping costs surged from $750 to $6,800 per container due to attacks in the Red Sea region[1].

- Pandemics: Pandemics can cause workforce shortages, disruptions in the transportation of materials, and reduction in production capacity. Pandemics can also lead to border restrictions that prevent product entry into a country.

Maintaining a resilient supply chain for image sensors is paramount for automotive manufacturers. Due to the limited availability of foundries capable of producing these specialized components, a disruption to the image sensor supply chain has the potential to cause a significantly broader and longer-lasting impact compared to that in the supply chain of more standard semiconductors.

Choosing the Right Supplier

Suppliers need to ensure reliable supply chains to maintain competitiveness and meet the growing demands of the automotive market. Automotive manufacturers must carefully consider their supplier’s production model to ensure supply chain resilience.

An internal manufacturing model follows an integrated approach, where the supplier manages the entire manufacturing process, starting from sourcing raw materials to producing image sensors. This offers a high-level of control over production processes but poses the risks of a single point of failure.

There are also suppliers who put their direct focus on research and development (R&D), leaving the physical manufacturing to external partners. This external manufacturing model offers increased flexibility and scalability because the manufacturer can utilize the unique capabilities of various companies, but it introduces challenges in quality control and creates a dependency on external partners.

An alternative, and most efficient method, is a hybrid model that leverages internal and external manufacturing advantages. This type of supplier employs a combination of in-house production and external collaborations for manufacturing. The dual-capability approach provides a middle ground between control and flexibility and ensures the highest level of supply assurance and resilience, along with various recovery options in the event of a disruption.

onsemi’s Hybrid Manufacturing Approach

onsemi, a leading manufacturer of image sensors , has the only secure CMOS image sensor facility in the US that is qualified by the Federal government. The company also employs a hybrid manufacturing approach to meet the demands of the automotive industry, combining its own in-house capabilities with trusted external partnerships in its global production network, ensuring a reliable supply of image sensors.

Wafer Fab

The production of image sensors starts at onsemi’s wafer fabrication facility located in East Fishkill, NY (Figure 2). This 300mm fabrication facility is specifically designed for precise assembly at any level of production. To meet increasing demand, onsemi continuously expands the capacity of their East Fishkill fab while also using 12″ wafers to enhance overall production capabilities.

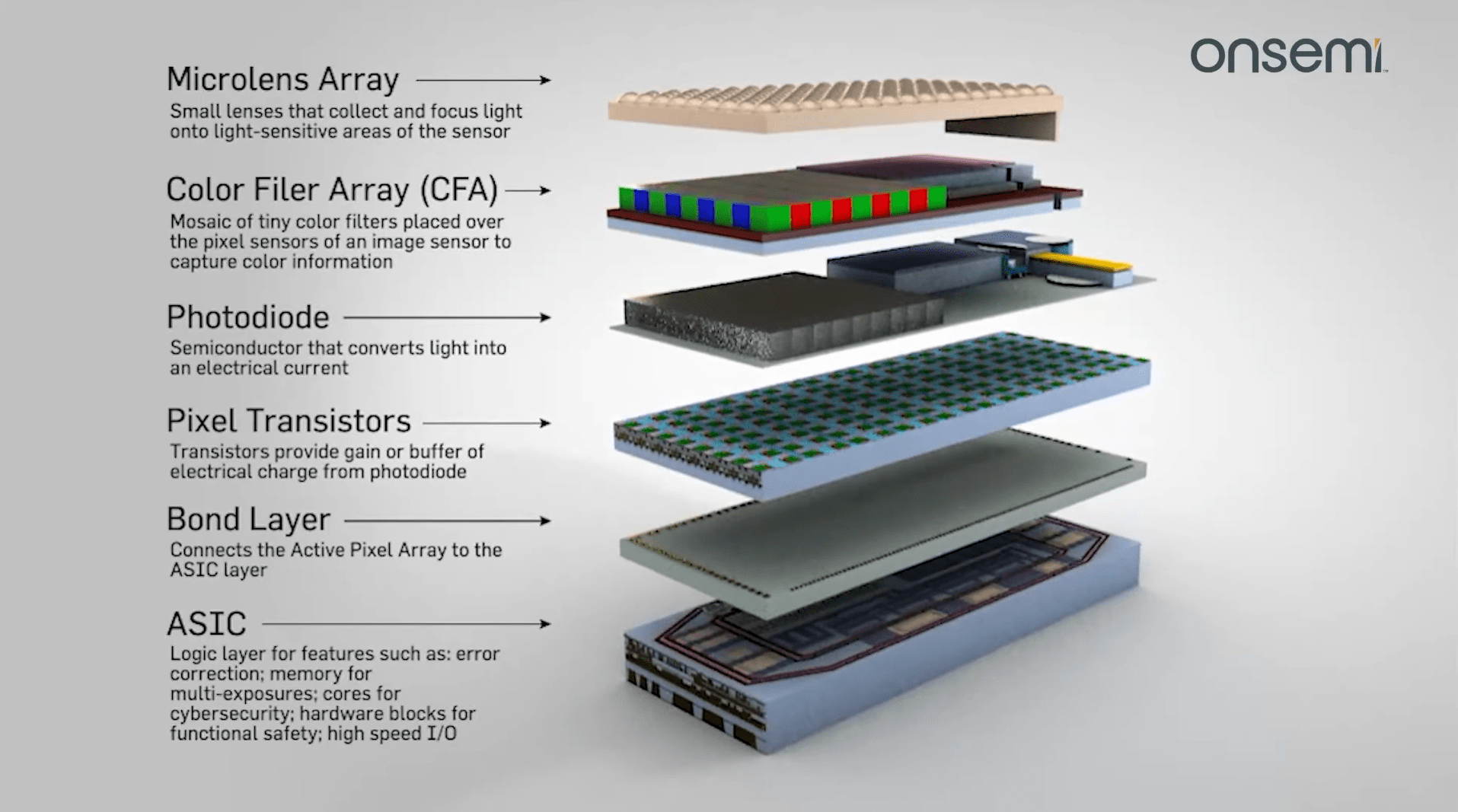

CFA and Microlens

onsemi upholds a dual capability in the production of Color Filter Array (CFA) and Microlens, operating facilities in both the USA and Malaysia. Having two manufacturing sites for CFA and Microlens creates strategic advantages and offers increased flexibility while reducing production risks.

Probe and Assembly

onsemi also provides dual-source options for wafer probe processes. With a specific focus on automotive-grade capability, onsemi’s wafer probe stage integrates stringent quality standards and testing protocols.

The assembly process is conducted within a Class 10 (one of the most stringent standards of cleanliness) cleanroom facility in Malaysia.

Final Test

To ensure outgoing quality assurance, onsemi conducts thorough testing on every finished component during the final test phase, ensuring its image sensor products meet rigorous automotive-quality standards before being released into the automotive market.

Continuous R&D and External Relationships

At the heart of onsemi’s hybrid manufacturing strategy lies an emphasis on internal R&D. This dedication to innovation enables the company to remain at the forefront of technological advancements, offering customers state-of-the-art solutions tailored to their designs and requirements. This is alongside strategic external relationships, with continuous collaboration helping to improve access to diverse technologies and nurture a culture of innovation and exploration.

Looking Ahead

As automotive manufacturers navigate the complexities of image sensor procurement, onsemi’s hybrid manufacturing model emerges as a robust solution. By carefully controlling every stage of the process, the company maximizes efficiency, ensuring high-quality production that guarantees a reliable and agile supply chain capable of meeting present and future automotive demands. Globally distributed production and key external partnerships fortify innovation and supply chain resilience.

By embracing innovative approaches and strategic partnerships, automotive manufacturers, with suppliers like onsemi, can help to mitigate risks and ensure a steady supply of image sensors for the vehicles of tomorrow.

Conclusion

Read our recently published brochure for a more in-depth look at the importance of selecting the right image sensor supplier for Automotive Manufacturers.

Download Here