With increasing consumer demands, electric vehicles (EVs) must extend their ranges to match those of traditional internal combustion engine (ICE) vehicles. There are two main approaches to address this issue: increasing the capacity of batteries without significantly adding to their size or weight or improving the operational efficiency of key high-power components, like traction inverters.

To combat the significant power loss caused by conduction and switching losses in electronic components, automakers are increasing the battery voltage as one of the ways to improve the vehicle’s range.

As a result, 800 V battery architectures are becoming more commonplace and might eventually replace the 400 V technology in use today. However, larger capacity batteries take longer to charge – which is another concern of drivers who have to wait too long for in-journey recharging to take place before they can reach their destination.

Therefore, in the same way that the battery voltage needs to advance, automotive OEMs must also keep pace with the on board charger (OBC) for EV. The first factor is the necessity to support 800 V battery architecture and handle higher voltages. This involves transition from today’s standard 650 V rated silicon components to ones that have a rating of up to 1200 V. Additionally, there is a growing demand for the OBC to have a higher power rating, enabling faster charging of the battery.

The Consumer Demand for Higher Performance

The OBC enables charging from AC power source like the grid by converting AC power into DC power. While the charging stations’ peak output is an obvious limitation for charging speed, as is the OBC’s peak power handling.

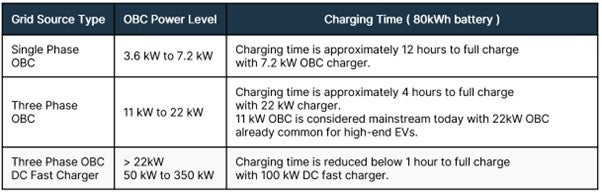

Among the current charging infrastructure, there are three levels of chargers:

- Level 1 offers a maximum of 3.6 kW

- Level 2 provides between 3.6 kW to approximately 22 kW, which matches the maximum capability of OBCs

- Level 3 operates through direct DC bypassing the OBC, delivering power in a range of 50 kW to 350+ kW

Despite the availability of faster level 3 DC charging stations, the use of OBCs will persist due to their limited global presence. Therefore, the increasing demand for more efficient OBCs is expected to persist, driven by the goal of maximizing the performance of existing Level 2 charging infrastructure and facilitating the adoption of higher voltage battery technology.

The data in Table 1 shows the most common OBC power levels and approximate charging time. The industry has shifted towards more powerful 3-phase OBCs to deliver faster charging, aligning with consumer demand. However, the actual charging time for an EV depends on several factors.

The key concept to understand is that charging isn't linear. As the battery approaches full capacity (typically above 80%), the charging profile slows down to protect battery health. In simpler terms, the fuller the battery, the slower it accepts energy. EVs often maintain a partial charge, and frequent 0-to-100% charging isn't recommended. Partially charging, up to 80% for instance, as suggested by many EV manufacturers, significantly reduces charging time. Furthermore, with the electrification trend extending to various vehicle types such as buses, vans, heavy-duty and agriculture vehicles, and even ships, the development of OBCs will push further into achieving even higher power levels exceeding 22 kW.

Automotive OEMs can enable faster charging at Level-2 stations by building a more powerful OBC, but this requires cost-effective and reliable electronic components with performance to deliver both significantly higher voltages (800 V vs 400 V) and higher power tiers.

Key Design Considerations for Higher Performance OBCs

For higher performance OBCs, there are a myriad of factors to consider beyond just power rating and battery voltage. These include thermal management, packaging constraints, component costs, electromagnetic compatibility (EMC), and potential needs for bidirectional functionality.

When it comes to thermal management, it is tempting to increase the size and weight of the OBC. However, this easy solution is not ideal since a bulky OBC may not fit well in the limited spaces of a modern EV, and additional weight will impact the vehicle’s achievable range.

Shifting to an 800 V battery architecture offers benefits like reduced conduction losses, providing performance boost, potentially faster charging and power delivery. However, it also introduces complexities for the designers:

- Component Availability: Finding components qualified for safe 800V operation can be challenging.

- Derating for Reliability: Even qualified components might need to be derated (operated below their maximum capability) to ensure long-term reliability.

- Safety Concerns: Higher voltage systems require robust insulation and safety features.

- Testing and Validation: Validating a high-voltage system is more complex and may require specialized equipment and expertise.

It is necessary to have components that have a higher breakdown voltage, specifically for the MOSFETs. Shifting towards high-performance Silicon Carbide (SiC) components proves to be beneficial in higher voltage applications that require faster MOSFET switching, such as OBC. It is also essential to factor in the voltage levels while developing the PCB layout, as this could entail enlarging the component spacing and the distance between PCB traces. Equally, other components (such as connectors, transformers, capacitors) that will be exposed to the higher voltage will also need to be rated higher.

Advancing OBC Designs to Achieve Greater Performance and Functionality

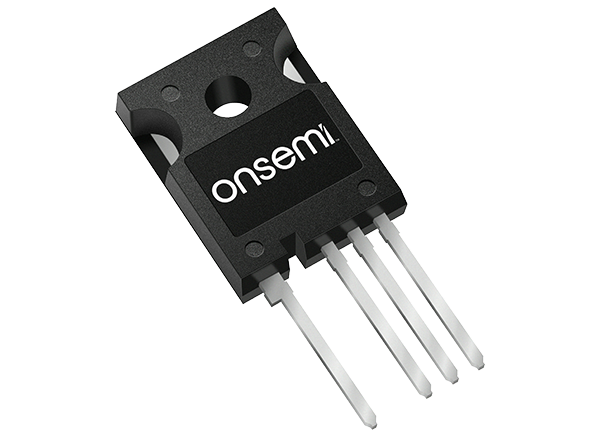

onsemi, a proven supplier of power modules for high-power automotive applications, is able to support the transition to 800 V battery systems. Its state-of-the-art EliteSiC 1200 V MOSFETs and Automotive Power Module (APM), enabling higher power density already have a proven track record across automotive designs.

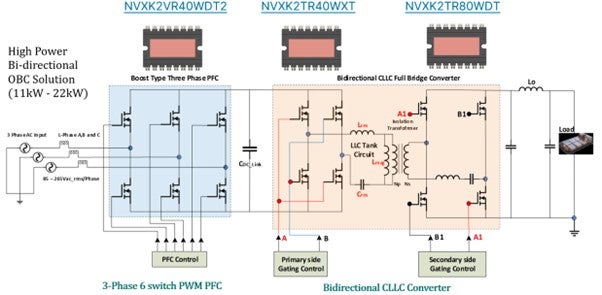

With the inclusion of onsemi’s cutting-edge 1200 V SiC devices, the APM32 power module family is optimized for 800 V battery architecture, and is suitable for higher voltages and power tier OBCs. The APM32 family includes 3-phase bridge modules for the power factor correction (PFC) stage, like the NVXK2VR40WDT2 , which features 1200 V 40 mΩ EliteSiC MOSFETs with integrated temperature sensing. This module is designed for 11 – 22 kW OBC end applications.

The APM32 module technology offers several advantages over discrete solutions, including a reduced form factor, improved thermal design, lower stray inductance, lower internal bond resistance, increased current capability, improved EMC performance, and increased reliability. By leveraging the APM32 modules, it is possible to create high-performance bi-directional OBCs (Figure 3). This not only enhances the functionality of a vehicle’s OBC, but also enables the EV to serve as battery storage on wheels.

The example OBC power stage shown in Figure 3 incorporates a boost type 3-phase PFC and a bidirectional CLLC full bridge converter to provide the necessary power and voltage handling, as well as the advanced bi-directional functionality.

As the world moves towards sustainable power sources, such as solar and wind, there may be times when the demand on the grid may exceed its capacity to deliver power. Electric vehicles with fully charged batteries offer a significant energy storage resource that can be harnessed to manage peak demands on the power grid or during emergencies when the primary power source of a building is compromised. By utilizing modules like the APM32 from onsemi, the OBC can allow for bidirectional energy transfer in EV batteries. As a result, the battery’s stored energy can briefly power a house before being recharged later.

Reliable Design and Supply

Unlike some competitors who outsource their packaging technology, onsemi internally designs and manufactures the APM lineup, which provides more control over thermal optimization. Manufacturers can also choose from a range of packaging and manufacturing options at onsemi, including the purchase of bare die, discrete components, or modules, ensuring there is an available suitable solution for any advanced OBC design.

Conclusion

OBC technology is advancing to support automotive manufacturers in meeting consumer demand for EVs, while also addressing new technology trends like 800 V battery architectures. By utilizing onsemi system solutions, such as the APM32 power modules, automotive designers can streamline their process and effectively address the latest demands, eliminating the need for extensive design efforts and ensuring the highest quality, reliability, and supply chain consistency.

In addition, onsemi provides a wide array of technical support, simulation and other power solutions that enable the development of a comprehensive, high-performance OBC design. These solutions include the EliteSiC 1200 V M1 and M3S MOSFETs, EliteSiC 1200V D1 and D3 Diodes, as well as complementary components like galvanically isolated gate drivers, CAN transceivers, and resettable fuses.

Download our OBC system solution guide to explore the wide variety of onsemi components and solutions for high performance OBC.

Additional Resources:

Featured