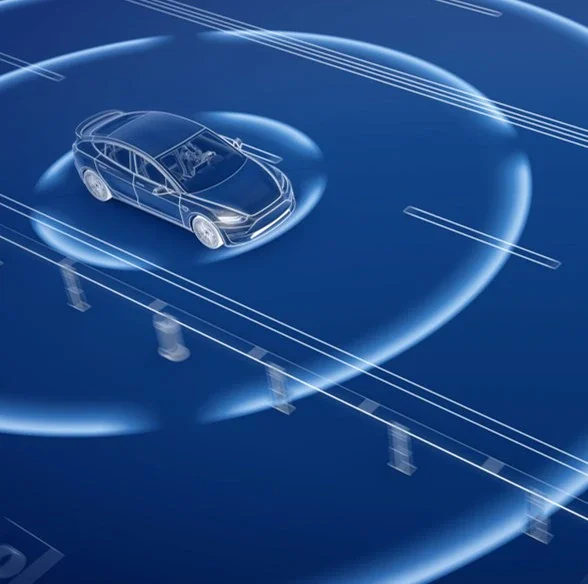

Light Detection and Ranging, or LiDAR, is a critical system for advanced driver assistance systems (ADAS) and autonomous driving (AD) vehicles, robotic mobility, and industrial automation. In ADAS and AD applications, LiDAR data is used to help make decisions that impact the safety and comfort of both vehicle occupants and other road users. For example, if a small dark obstacle is detected on the road ahead, the vehicle needs to be able to detect this at a sufficient distance to make a stop safely, including under challenging environmental conditions.

LiDAR works by actively illuminating the surroundings and measuring the time taken for the reflected photons to return to the sensor. The rate of returned photons decreases with a square relationship to the distance traveled. For LiDAR to be effective, the sensor must maximize the efficient use of those returned photons. A typical use case is detection of a 10% reflective target at 300 m with angular resolution <0.1° in a 120° x 20° field of view (FoV) and centimeter precision at 20 frames per second (fps) rate.

Silicon photomultiplier (SiPM) sensors are highly efficient light sensors that confer single photon detection capability on the receiver. SiPM-based LiDAR offers a remarkable signal-to-noise ratio (SNR) advantage over legacy sensors, such as avalanche photodiodes (APD). SiPM’s high internal gain and fast response time allow for higher detection probability of low reflective targets at long distances. This significant improvement is achieved without the need to increase the outgoing laser power requirement, thereby reducing system power requirement and thermal management burden.

Furthermore, this higher SNR is achieved using a smaller aperture (smaller optical lens) to optimize light collection, compared to using a wider aperture required by APD. This means the physical system size can be reduced by implementing SiPM. This is helpful where restrictions apply to the physical design and dimensions of the LiDAR system e.g., ADAS and robotics.

Other SiPM benefits include low operating voltage and low sensitivity to temperature. They are especially important in automotive applications where the LiDAR environment can be >85°C. SiPMs are based on standard silicon processes that enable low-cost device production with excellent device uniformity. These benefits can help to simplify the LiDAR design complexity while maximizing performance and reducing cost.

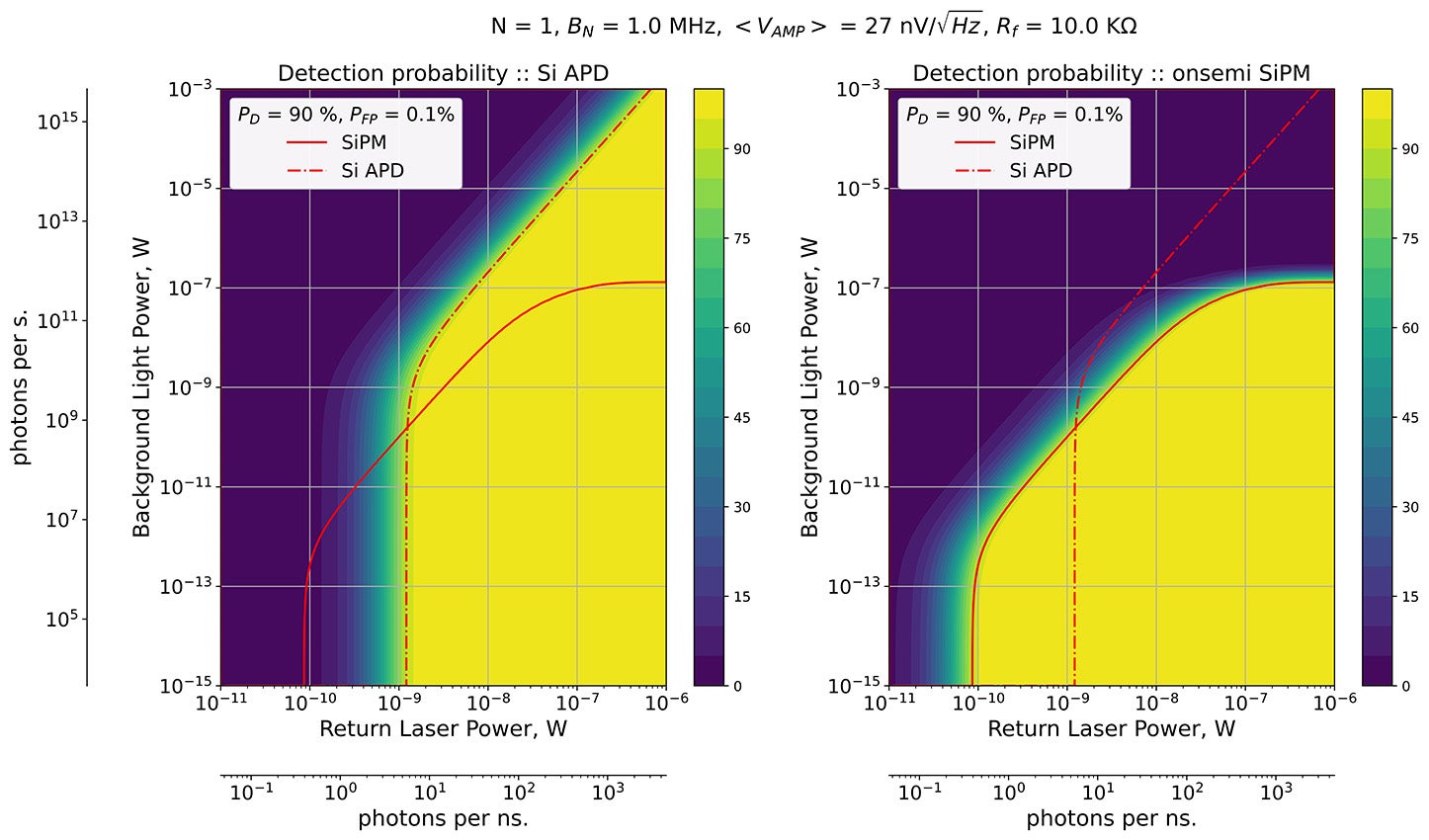

We compared the relative performance of APD- and SiPM-based LiDAR systems, with a common set of system-level requirements. (Comparison of key parameters is presented in Table 2). The operating voltage of SiPM is almost 1/10 smaller than that of APD; device-to-device performance is uniform and bias voltage variation with temperature is typically 25 mV/°C. Due to its high internal gain, the performance of the SiPM-based LiDAR system is much less dependent on read-out electronics performance. According to our modeling analysis, the SiPM readout can accommodate 2 orders of magnitude higher electronic noise compared to the APD readout (See our application note for details).Also due to four orders of magnitude higher gain, SiPM system could work at a much higher bandwidth allowing improved depth calculation precision and increased scanning speed. Thanks to single photon sensitivity, SiPM-based system, on average, requires one order of magnitude less return laser power to reach the same detection probability as APD-based system, as shown in Figure 1. This improved detection capability can lead to increased ranging capability or decreased laser power requirement.

A typical requirement is for the LiDAR to operate under 100 klux corresponding to the ambient light level on a bright sunny day. Due to its high sensitivity, the SiPM sensor may be saturated if exposed to very high light levels. This would be a problem if saturation due to ambient light prevented detection of an object. The SiPM-based system can be designed to operate under 100 klux ambient conditions by employing a narrow bandpass filter combined with a small aperture lens and a narrow angular field of view. These design solutions align well with existing trends in LiDAR system requirements i.e., miniaturization (small lens diameter) and high angular resolution (small angular FoV per SiPM).

With our extensive LiDAR modeling expertise, we conclude that SiPM-based system:

- Is one order of magnitude more sensitive to return laser light.

- Allows the use of optical lens with a much smaller aperture (for system miniaturization).

- Shows lower dependence on read-out system performance simplifying the system level design.

To learn more about how onsemi SiPM sensors can benefit your next LiDAR system design contact onsemi sales and applications teams.

Additional design resources: